Go Direct Wide Range Pressure

GDX-WRPL is liquid & gas compatible

GDX-WRP is gas compatible only

Specifications and User Guide

TROUBLESHOOTING

-Primary Test: Connect the sensor to a Vernier interface and run the data-collection program. The units for the default readings are kPa and they should be reasonable for the altitude at which the sensor is being used (around 101 kPa at sea-level). If you plug the output with your finger, the pressure should rise slightly (~5 kPa).

SPECIFICATIONS

Range: 0 to 690 kPa

Maximum pressure can withstand: 900 kPa

Accuracy using factory calibration: +/- 2 kPa

Accuracy using custom calibration: +/- 1 kPa (1 point calibration at atmosphere)

Temperature range: -40 degC to 125 degC

Gas Compatible (GDX-WRP): Dry gases only

Liquid & Gas Compatible (GDX-WRPL): Dry gases and Parylene C Coating liquid compatibility

Internal volume of sensor with 1/8” NPT Thread Insert attached: 0.786 mL

Internal volume of sensor with 1/8” Hose Barb Insert attached: 0.623 mL

Accessories included:

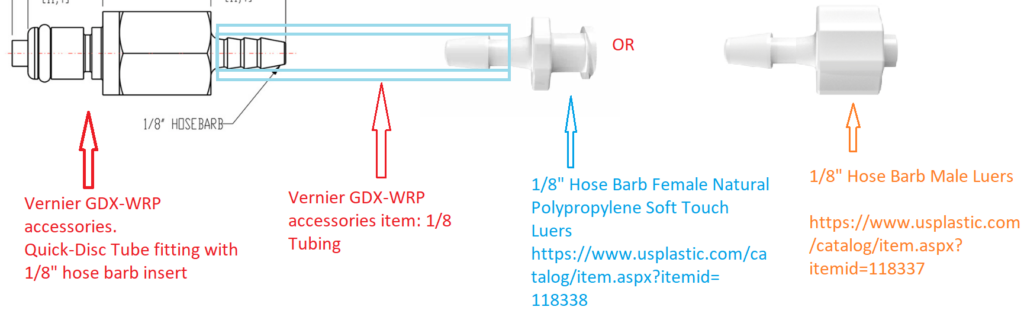

- Chrome-plated Brass Quick Disconnect Tube Fitting with 1/8” NPT thread insert

- Chrome-plated Brass Quick Disconnect Tube Fitting with 1/8” hose barb insert

- Two-foot section of plastic tubing: This soft tubing is designed to fit over the hose barb connector. Its standard size allows you to connect to a variety of third-party instrumentation or adapters.

- Plumber’s tape: This 1/2″ sealing tape should be wrapped around the threading on the pressure sensor. Wrap only once and to the right, as the threading runs. This will help ensure an airtight seal.

What liquids can I use with the GDX-WRPL?

Liquid Compatibility – Parylene C Coating

The GDX-WRPL features a Parylene C coating, renowned for its excellent chemical resistance and barrier properties. This coating provides protection against a variety of chemicals, making the sensor suitable for numerous laboratory applications. However, it’s essential to understand its compatibility limits to ensure the longevity and accuracy of the sensor.

Compatible Liquids (Short-Term Exposure):

- Water (distilled, deionized)

- Dilute acids (e.g., hydrochloric acid, sulfuric acid, nitric acid at concentrations ≤10%)

- Dilute bases (e.g., sodium hydroxide, ammonium hydroxide at concentrations ≤10%)

- Alcohols (e.g., isopropyl alcohol, ethanol)

- Hydrogen peroxide (≤3%)

- Aliphatic hydrocarbons (e.g., n-octane)

- Aromatic hydrocarbons (e.g., toluene, chlorobenzene)

- Ketones (e.g., acetone)

Use with Caution:

- Concentrated acids and bases: May cause swelling or degradation over extended exposure.

- Strong oxidizers: Can affect the integrity of the coating.

- High-temperature solvents: Elevated temperatures can increase the permeability of the coating.

Not Recommended:

- Prolonged exposure to aggressive solvents: Such as benzoyl benzoate or x-chloronaphthalene, especially at temperatures above 150°C.

- Mechanical cleaning agents: Abrasive materials can damage the coating.

Best Practices:

- Rinse after use: Always rinse the sensor with distilled water after exposure to chemicals to prevent residue buildup.

- Avoid prolonged immersion: Limit the duration of exposure to compatible liquids to prevent potential degradation.

CALIBRATION

Go Direct Wide-Range Pressure is calibrated to true atmospheric pressure before shipping. If you wish to recalibrate to sea level pressure based on your elevation, perform a one-point calibration using a known value.

1. Connect the sensor to an interface and launch the software.

2. Initiate the calibration procedure.

3. Enter the known calibration value in the box.

4. Once the relative stability reading in the input field stops changing significantly, click Keep to record the input value.

5. Click Apply to complete the calibration process. This calibration is automatically stored to the sensor. To restore the default calibration, click Reset to Defaults.

RELATED VERNIER PRODUCTS

Go Direct® Gas Pressure Sensor (GDX-GP)

Pressure Sensor 400 (PS400-BTA)

If you wish to purchase different quick disconnect inserts or replacements, many are available and compatible with the sensor. Contact chemistry@vernier.com for recommendations.

Unfortunately, there is not a quick disconnect luer lock option at this time. Below is an option for a luer lock set up: