Sharing ideas and inspiration for engagement, inclusion, and excellence in STEM

When it comes to innovation, CASE educator Jamie Christiansen and her agricultural science students are bringing home the bacon—and the data—to help local pork farmers thrive. Christiansen, who teaches in the Midland Community School District in Wyoming, Iowa, is passionate about hands-on, inquiry-based learning that connects students directly with real-world agricultural challenges in their community.

Recently, her students took on a unique problem: creating a science-based investigation to produce reliable data that could help market locally produced pork.

“As farmers and producers in our area, we already know the quality of the meat and produce we’re raising and growing,” Christiansen explains. “But we had a community member—a former student—who wanted more than just word-of-mouth to help market his pork. He wanted data to show why people should pay a little more than at the grocery store to buy pork from him.”

Meeting the Challenge with Data-Driven Inquiry

Christiansen brought this request to her Agricultural Research and Development (ARD) students and let them take the lead in brainstorming a solution.

“It was awesome just to watch the kids go through the process: what does he want to know? What can we do? How do we set this up?” Christiansen says.

As a capstone course, ARD challenges students to combine practice and theory as they develop a solution to a real-world industry problem—in this case, a marketing and sales challenge that students could really sink their teeth into. They took projects and Vernier sensors from previous CASE classes, like Introduction to Agriculture, Food, and Natural Resources (AFNR) or Food Science and Safety (FSS), to develop a strategy that ensured they’d get accurate and reliable data.

“The students were really driving all the tests and figuring out how to use different sensors or to measure different variables,” Christiansen adds. “I only needed to jump in to ask guiding questions when they were getting stuck.”

Developing Experiment Parameters and Protocols

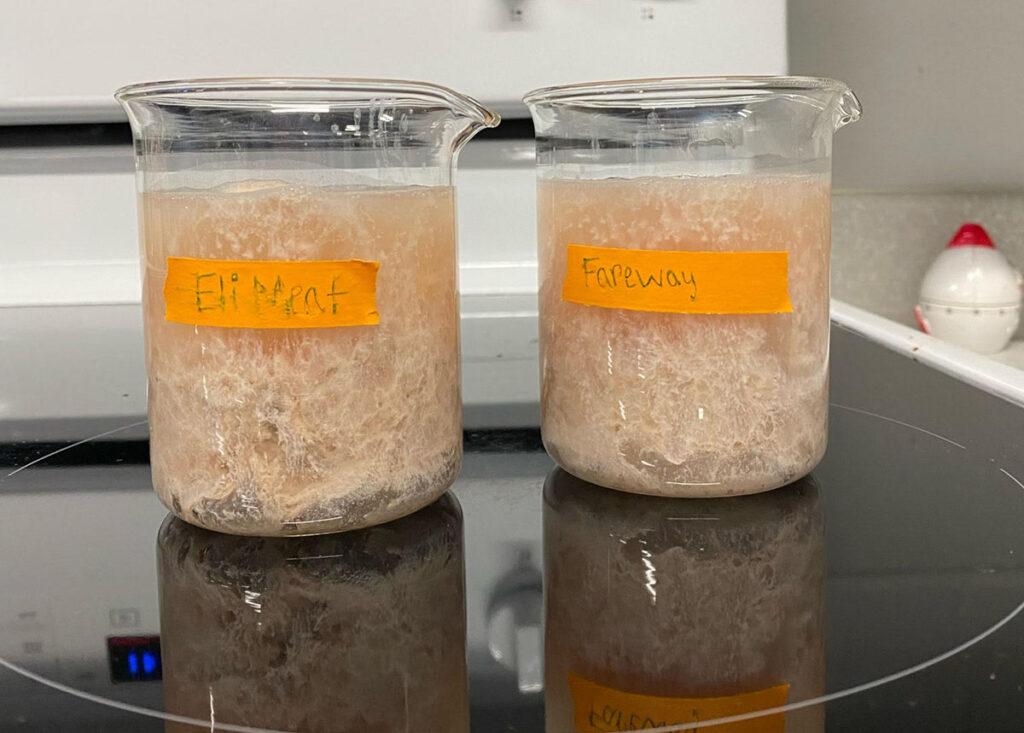

As part of the project, students developed protocols for data collection—identifying variables, selecting tools, and setting standards for data quality. They chose six key metrics to compare between the local Berkshire pork samples and store-bought cuts: fat percentage, water weight, tenderness, appearance, taste, and pH.

They also made a plan to ensure the quality of their data by controlling variables like grilling temperature, sample size, and sample weight to maintain consistency across tests.

“They did a fat test, dehydrated and checked moisture levels, and even tested pH,” Christiansen recounts. “But once we got to tenderness—we had to ruminate a bit. How could we get accurate, quantitative data?”

After brainstorming some options with other CASE educators, Christiansen landed on a creative solution: using a Vernier Force and Acceleration Sensor to measure tenderness.

meat tenderness.

“It was really interesting!” Christiansen remarks. “The students experimented a lot—first with bread, then with different fruits, to practice using the sensor without wasting the meat. Then they figured out calculations for how far to push the meter down into the food. They looked at the cooking temperatures, looked at the thickness of the meat, and things like that to make sure that we were actually testing that chew factor.”

The Results and a Flavorful Finish

While it wasn’t a clean sweep in every category, the local pork shined in several areas critical to consumer satisfaction. These results not only provided the farmer with valuable marketing data but also gave students an appreciation for data-driven decision-making.

“It did come out on top in tenderness and appearance, which were big wins for the farmer,” says Christiansen. “And with the higher fat percentage, he was actually very pleased—it’s part of what makes Berkshire pork so flavorful.”

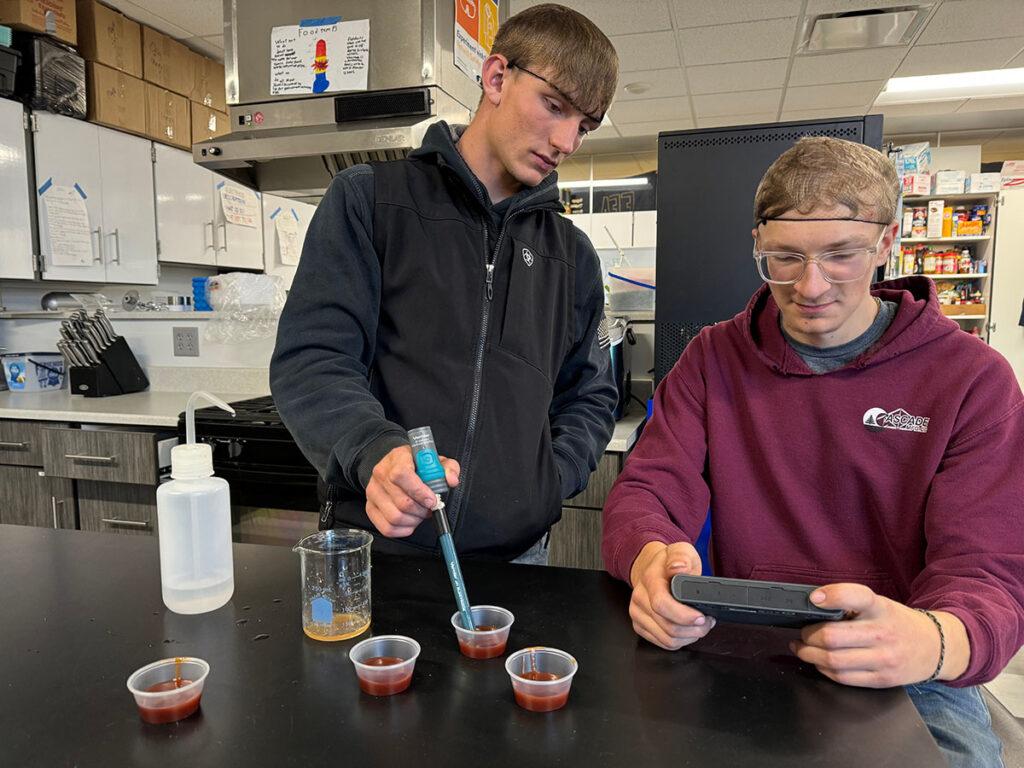

Christiansen’s class has even ventured into producing their own BBQ sauce! They bottled it according to Iowa Cottage Law, and sold it as a fundraiser, using Vernier Go Direct® pH sensors to check compliance with state regulations.

and a LabQuest interface.

“Every competition we went to, people would say, ‘Your meat is good, but your sauce is amazing,’” Christiansen laughs. “So we started bottling it, and the kids tested each batch to ensure the pH met the 4.60 or lower requirement—all of ours were between 3.2 and 3.6—but they always tested each batch so we could put the exact pH on the packaging label.”

Empowering Students Through Real-World Learning

With 20 years of teaching experience, Christiansen is passionate about using student-led teaching strategies to help foster critical thinking and problem-solving in her students. Through her instruction, she shows students that science is not just about learning facts—it’s about questioning, investigating, and finding meaning in data, especially in an agricultural setting where this information can directly benefit their community.

sponsored by Vernier Science Education.

“I just really love teaching because every day’s different, every block’s different, and I get to introduce kids to new and interesting topics,” Christiansen shares. “I find it very important to get the kids engaged, asking and answering their own questions, figuring things out for themselves.”

For other CASE and agricultural education teachers, she advises embracing hands-on tools to support student inquiry.

“Some new teachers might be nervous about using equipment, but Vernier sensors are so easy and user-friendly,” she explains. “Students get the hang of it quickly. They’re great tools to have, especially in small groups. We have a few of the wireless Go Direct® sensors, too. Students like them, and I do even more—they cut down on cords and chaos!”

Learn more about how Vernier supports agricultural science, CASE, and other career and technical education. Questions about our sensors? Reach out to support@vernier.com, call 888-837-6437, or drop a question in our live chat!

Share this Article

Sign up for our newsletter

Stay in the loop! Beyond Measure delivers monthly updates on the latest news, ideas, and STEM resources from Vernier.